Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

November 15, 2024

NTT Corporation

Lineup of multi-core optical fiber construction, operation, and maintenance technologies that realize four times the capacity with a single optical fiber

The world's first automatic rotation alignment connection and branching/connecting technology with existing optical fibers

News Highlights:

- We have made significant progress in solving construction, operation, and maintenance technology issues in an actual field environment, which were issues before the commercial introduction of multi-core optical fiber (MCF)1.

- Specifically, we have developed a lineup of technologies for automatic rotation alignment connection of MCFs, interconnection and branching technology between MCFs and existing optical fibers, connection and branching technology between MCFs and existing optical cables, and in-station MCFs accommodation and wiring technology.

- This is expected to accelerate the practical application and international standardization of the MCF optical transmission line that supports the IOWN's large-capacity optical transmission.

TOKYO - November 15, 2024 - NTT Corporation (Headquarters: Chiyoda Ward, Tokyo; Representative Member of the Board and President: Akira Shimada; hereinafter "NTT") has developed a lineup of on-site construction, maintenance, and operation technologies essential for the commercial introduction of four-core multi-core optical fiber (MCF) optical transmission lines, which enable a single communication optical fiber to have four times the capacity of current optical fibers. This achievement is expected to accelerate the practical application of four-core MCF optical transmission lines in inter-data center optical communications, where the demand for optical fiber cores continues to grow exponentially, and in submarine optical transmission sections, where optical fiber mounting space in optical cables is limited.

Part of the research results will be exhibited at NTT R&D FORUM 2024 - IOWN INTEGRAL2 to be held from November 25-29, 2024.

Background

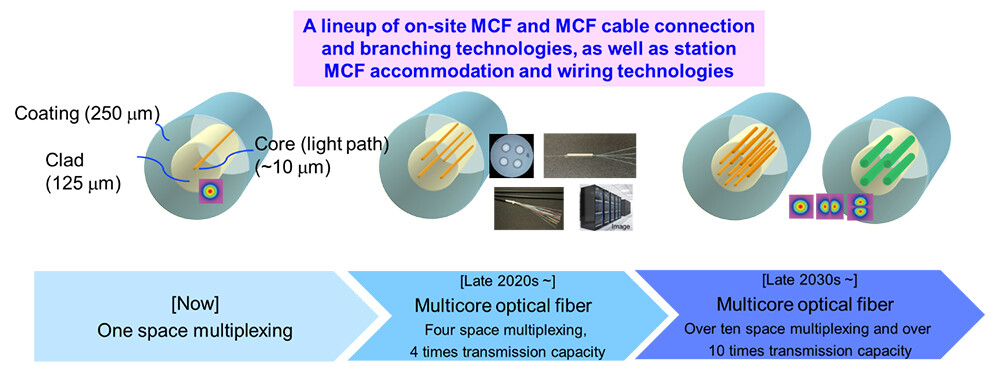

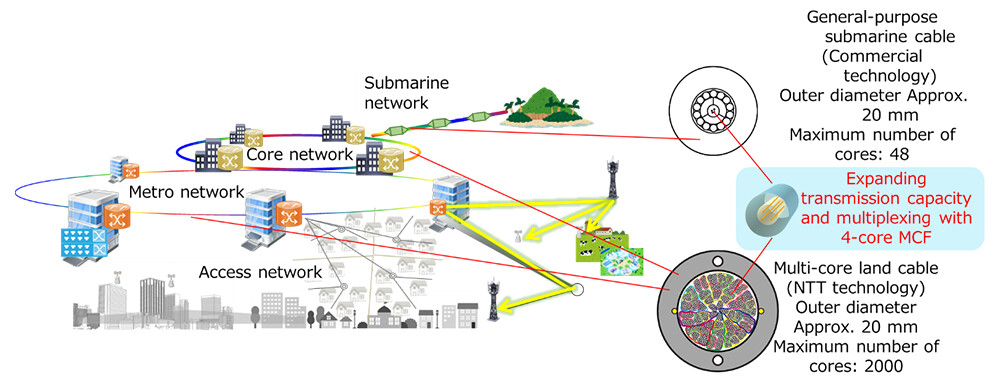

NTT is conducting R&D on MCF, which is one of the underlying technologies for realizing the high-capacity optical transmission infrastructure of the IOWN Initiative3 to realize a world of well-being. To date, NTT has been conducting R&D on a four-core MCF that multiplexes four optical paths in glass as thin as current optical fibers (Figure 1). To date, the establishment of on-site construction, maintenance, and operation technologies has been an essential issue at the stage of commercial introduction of four-core MCF optical transmission lines. For example, since the core of an MCF is located at a location other than the center of the optical fiber section, it is essential to align the rotational direction and align the corresponding four-cores to connect MCFs. In addition, at the beginning of the introduction of the MCF optical transmission line into the land optical transmission system, the technology for interconnecting the MCF optical transmission line with the existing optical fiber with one core is essential.

In addition, rapid response to accidents and breakdowns requires that these interconnection technologies be established at a level that is available on-site.

Figure 1 Optical Fiber Technology Roadmap to Achieve the Larger Capacity of IOWN

Figure 1 Optical Fiber Technology Roadmap to Achieve the Larger Capacity of IOWN

Underlying technologies for the construction, maintenance, and operation of four-core optical transmission lines

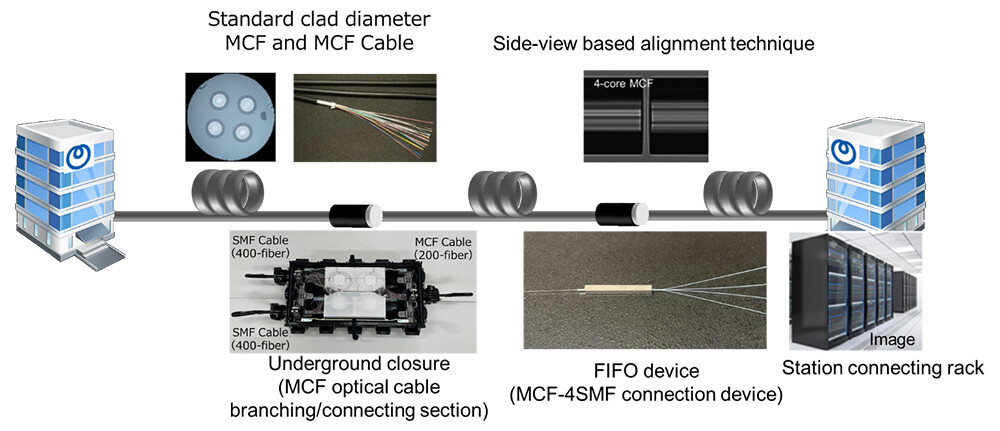

In addition to the design of the four-core MCF and its mounting on optical cables, we have developed a lineup of connection and branching technologies that enable on-site construction, maintenance, and operation, as well as cable connection and branching technologies that use these technologies, and in-station MCF accommodation and wiring technologies (Figure 2).

Figure 2 Underlying Technologies Required for Construction, Maintenance, and Operation of Four-core Optical Transmission Lines

Figure 2 Underlying Technologies Required for Construction, Maintenance, and Operation of Four-core Optical Transmission Lines

In addition to MCF technology, which is the core technology of the four-core optical transmission line, and MCF technology, which multiplexes four cores with the same thickness as current optical fibers, and high-density optical cable technology, which enables mounting up to 8,000 cores (2,000 cores of four-core MCF) in a diameter of approximately 20 mm, we have established two underlying technologies for MCF connection and branching.

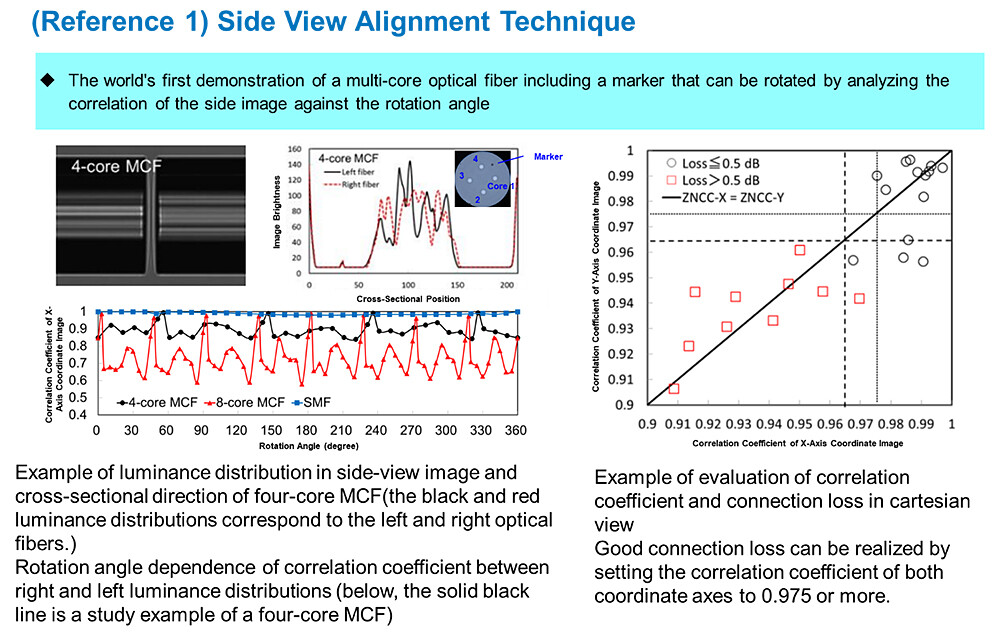

Side-view based angle alignment technique4: The position of the four-cores is identified by observing and analyzing the side views of two opposing four-core MCFs, and the positions of the opposing cores are automatically rotationally aligned. By incorporating this technology into a general-purpose fiber-optic fusion splice connector, permanent connections between MCFs can be realized on-site as well as in laboratory environments and factories.

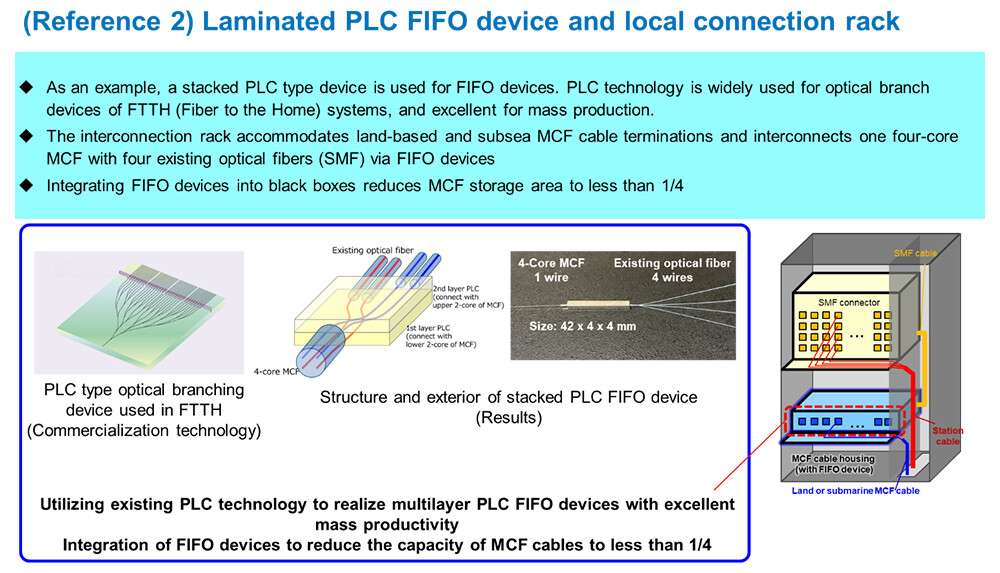

FIFO (Fan-in-Fan-out) Device Technology5: In collaboration with NTT Innovative Devices, we have achieved inter-junction and branching between a single four-core MCF and four existing optical fibers with one core using a unique two-layer structure consisting of stacked quartz-based PLC (Planar Lightwave Circuit) waveguides. Quartz-based PLC waveguides are also widely used for optical power branching in existing optical transmission systems, and have high reliability and excellent mass productivity.

Furthermore, we have established underlying technologies for optical transmission lines in underground pipelines and in stations by utilizing the above-mentioned connection and junction technologies.

MCF cable connection and branching technology (Underground closure): This technology enables connection and branching of thin-diameter high-density optical cables with MCF or existing SMF (Single Mode Fiber) cables in underground facilities. Because the four-core MCF is as thin as the existing optical fiber, the outer diameter of the MCF cable can be unified with that of the existing optical fiber cable, and the basic structure of the existing underground closure can be efficiently used for MCF of the underground closure.

In-station MCF accommodation and wiring technology (in-station connection): MCF cables are terminated at in-station facilities and interconnected with existing optical fibers via the aforementioned FIFO devices. In addition, by using MCF as the housing unit of the connecting rack and black-box FIFO devices, the housing area can be integrated to 1/4 or less5.

Areas of application of results

This result is expected to be applied to data center networks, where the number of optical fibers used continues to increase exponentially, and to submarine optical cables, where the number of optical fibers that can be mounted is limited in space (Figure 3). In data center networks, demand for optical cables with thousands of optical fibers is becoming apparent. As the number of optical fibers mounted increases, the diameter of optical cables is also expanding. For example, the diameter of cables that can be installed in underground pipelines is approaching the upper limit. In addition, the number of optical fibers that can be mounted on submarine optical cables is limited to a few dozen, and the latest submarine optical systems have already reached the maximum number of optical fibers that can be accommodated. By applying the four-core MCF to such areas, it is possible to flexibly respond to the demand for core wires in land-based systems and the demand for large capacity in subsea systems.

Figure 3 Example of Areas Where Practical Application of Four-core Optical Transmission Lines Is Expected

Figure 3 Example of Areas Where Practical Application of Four-core Optical Transmission Lines Is Expected

Outlook

This research result enables on-site construction, maintenance, and operation of four-core optical transmission lines, and is expected to greatly accelerate the practical deployment of four-core optical transmission lines. We aim to promote the practical deployment and international standardization of four-core optical transmission line technology by around 2027.

[Glossary]

1.Example of research and development of multi-core optical fiber (MCF)

https://group.ntt/en/newsrelease/2017/08/08/170808b.html

2."NTT R&D FORUM 2024 - IOWN INTEGRAL" Official Website

https://www.rd.ntt/e/forum/2024/

3.Innovative Optical and Wireless Network (IOWN) Initiative

https://www.rd.ntt/e/iown/

4.Side-view based angle alignment technique (Reference 1)

If the core is placed at a location other than the center of the optical fiber, such as a four-core MCF, it is necessary to align the rotational axis direction to connect the optical fibers. In the past, it was common to directly observe the end face of an optical fiber to perform alignment in the direction of the axis of rotation, but it was difficult to incorporate an optical system for observing the end face into a compact and portable fusion splice connector. In this research, we analyzed the luminance distribution obtained from the side view of a four-core MCF and automatically derived the rotation angle at which the luminance distribution of opposing four-core MCFs coincides. Also, in connection with a four-core MCF, a reference point called a marker is required to number each core in the cross section, but the proposed technology can realize automatic rotation alignment including the marker. This enables fusion splice connection of four-core MCFs by simply incorporating an image analysis mechanism into an existing compact and portable fusion splice connector.

https://ieeexplore.ieee.org/document/7537268

5.FIFO (Fan-in-Fan-out) device technology and in-station MCF accommodation and wiring technology (in-station connection) (Reference 2)

Quartz-based PLC waveguides can be mass-produced by forming two-dimensional optical waveguides on glass substrates. For this reason, it is widely used in devices that branch a single optical fiber signal into multiple paths in FTTH (Fiber to the Home) systems. In this result, we have achieved a structure in which quartz PLC is stacked in the height direction and two cores are interconnected and branched in the first and second layers, respectively. By incorporating this technology into the connecting rack in the station and connecting the four-core MCF directly to the connector, the cross-sectional area required for connection can be reduced to less than 1/4 of that of existing optical fibers.

https://journal.ntt.co.jp/backnumber2/0505/files/jn200505016.pdf

https://ieeexplore.ieee.org/document/7121461

About NTT

NTT contributes to a sustainable society through the power of innovation. We are a leading global technology company providing services to consumers and businesses as a mobile operator, infrastructure, networks, applications, and consulting provider. Our offerings include digital business consulting, managed application services, workplace and cloud solutions, data center and edge computing, all supported by our deep global industry expertise. We are over $97B in revenue and 330,000 employees, with $3.6B in annual R&D investments. Our operations span across 80+ countries and regions, allowing us to serve clients in over 190 of them. We serve over 75% of Fortune Global 100 companies, thousands of other enterprise and government clients and millions of consumers.

Media contact

NTT Information Network Laboratory Group

Public Relations

https://tools.group.ntt/en/rd/contact/index.php?param01=R¶m02=302

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT