Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

May 12, 2025

NTT Corporation

NTT EAST Corporation

NTT AgriTechnology Corporation

Remote Operation of a Harvesting Robot via Edge Computing-Based Quality Control

-- Contributing to the advancement of user-friendly smart agriculture --

News Highlights:

- A robot operator based in Tokyo successfully conducted a demonstration in which they remotely operated a harvesting robot located in a strawberry field in Akita Prefecture—approximately 400 km away in a straight line—while viewing video enhanced with image processing to assess strawberry ripeness.

- Despite fluctuations in network quality, the operator was able to maintain high operability and accurately harvest strawberries without causing any damage.

- By integrating the network and server for edge computing-based quality control, even advanced harvesting tasks could be performed remotely, contributing to the realization of user-friendly smart agriculture.

TOKYO - May 12, 2025 - NTT Corporation. (Headquarters: Chiyoda, Tokyo; President and CEO: Akira Shimada; hereinafter "NTT"), NTT EAST Corporation (Headquarters: Shinjuku, Tokyo; President: Naoki Shibutani; hereinafter "NTT EAST"), and NTT AgriTechnology Corporation (Headquarters: Shinjuku, Tokyo; President: Taiga Sakai; hereinafter "NTT AgriTechnology") conducted a demonstration experiment in which a harvesting robot located in a field in Akita Prefecture was remotely operated over a network from Tokyo—approximately 400 km away in a straight line—to harvest strawberries.

This experiment confirmed that real-time motion control based on network quality enabled stable and highly operable remote harvesting.

The success of this demonstration suggests that remote operation can be applied not only in agriculture but also in a wide range of fields, contributing to the resolution of labor shortages.

This technology will be exhibited at Tsukuba Forum 20251, to be held on May 15-16, 2025.

Background

Japanese agriculture is currently facing a serious labor shortage due to a declining and aging workforce. In response, the adoption of smart agriculture technologies is accelerating.

Until now, smart agriculture has mainly focused on stabilizing crop yields by optimizing the timing and amount of watering and fertilization. However, much of the fieldwork still relies heavily on manual labor. As a result, there is a growing need to reduce the workload through the use of agricultural robots.

In particular, plant-based agriculture poses unique challenges for automation, as tasks such as harvesting and pesticide application often require nuanced human judgment. This makes the use of remotely operated robots, which can incorporate human decision-making, especially important.

In this demonstration, we envisioned farm support workers performing harvesting operations remotely and took on the challenge of verifying the operability of a remote-controlled harvesting robot.

To make remote operation practical, it is essential not only to reduce network and server latency but also to visualize otherwise invisible factors—such as network delays—through image processing to support smooth operation and accurate harvesting decisions.

Furthermore, in scenarios where heavy system loads cause unavoidable latency increases, mechanisms that maintain operability without performance degradation are key to the widespread adoption of remote operation technologies.

Against this backdrop, we conducted a proof-of-concept aimed at enabling remote farm support workers to perform smooth and efficient harvesting by using agricultural robots equipped with AI-powered image processing.

Overview and Results of the Demonstration Experiment

In this demonstration, we established a remote harvesting environment in which an operator in Tokyo controlled a robot located in a strawberry field in Akita Prefecture, using video transmitted via a network. A camera mounted on the harvesting robot captured video footage, which was analyzed by an image processing server to determine whether each strawberry was ready for harvest. This judgment was overlaid on the video feed. The operator used this enhanced video displayed on a monitor to remotely control the robot and harvest strawberries in Akita.

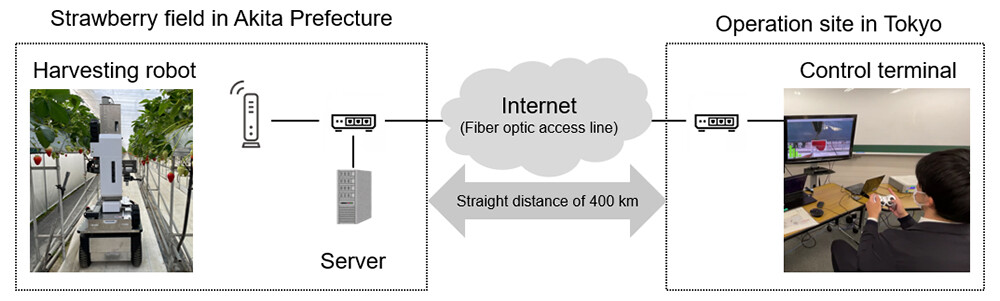

The system configuration included a harvesting robot and image processing server installed in the strawberry field in Akita, and a control terminal located at a site in Tokyo. The two locations, approximately 400 km apart in a straight line, were connected via fiber optic access and internet lines (Figure 1).

Under these conditions, we confirmed that the robot could be remotely operated with high precision, enabling strawberries to be harvested without damage.

Additionally, we implemented a feature in the system that adjusts both the monitor display and the robot arm's speed according to end-to-end network delay. We then evaluated how much this feature improved operability during strawberry harvesting.

Specifically, we measured the success rate—defined as the percentage of times the robot arm could be moved accurately to a strawberry's position in a single attempt. In environments with fluctuating delays, the success rate was approximately 50%. By utilizing this feature, the success rate improved to about 80%, representing a 30% increase.

Furthermore, all five test participants reported that they perceived a clear improvement in operability due to the new feature.

Figure 1 Configuration of Remote Harvesting System

Figure 1 Configuration of Remote Harvesting System

Key Technologies

The high-speed closed-loop control technology for network and computing2 enables real-time monitoring of both processing time at the edge server and network delay. When the end-to-end delay exceeds performance requirements, the system instantly switches to an alternative route and server process, maintaining a stable, low-latency service. In this demonstration, the technology was enhanced and adapted for use in smart agriculture applications.

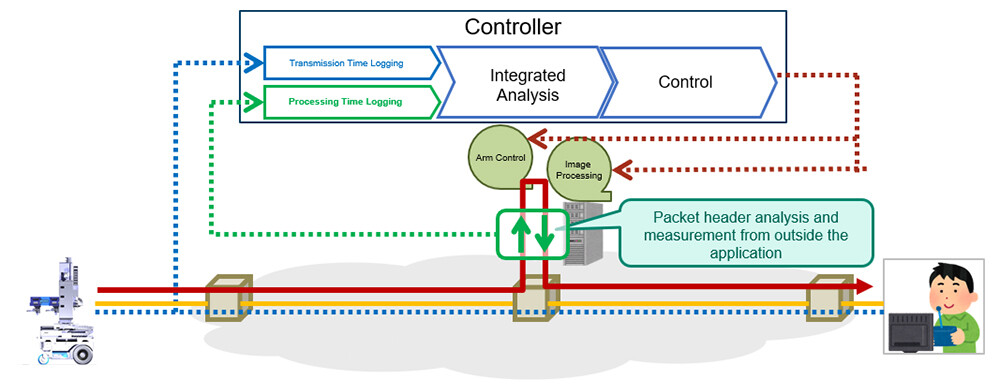

- Measuring Processing Time Outside the Application

Traditionally, processing time for image recognition was measured by adding custom functionality to the image processing application and linking it to the system. With this enhancement, it is now possible to analyze input/output data outside the application using standard image frame header characteristics, allowing the calculation of processing time based on data passage. As a result, processing time can now be measured entirely by the external server, without modifying the image processing application itself (Figure 2).

Figure 2 System Integration Function

Figure 2 System Integration Function

- System Integration via Quality Notification

Previously, when communication quality failed to meet performance requirements, the system automatically switched to a different route or server process. The enhanced version allows real-time notification of communication quality to the remote harvesting system, enabling the system itself to adjust behavior accordingly.

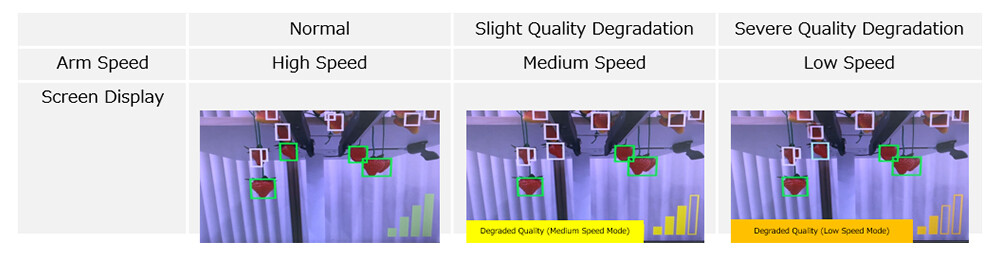

This feature classifies communication quality into three levels based on real-time analysis and sends that information to the remote harvesting system. As shown in Figure 3, communication quality is visually overlaid onto the video stream from the robot to the operator's terminal, providing timely updates to the operator.

Additionally, the control information for the robot arm is adjusted based on the communication quality: the arm is slowed or stopped when necessary. This allows the operator to understand the current system condition and reduces operational stress, even when end-to-end delays increase.

Furthermore, since control precision tends to decline with higher delay, adjusting the robot arm speed helps mitigate error, contributing to more stable operation under adverse conditions.

Figure 3 System Integration Function

Figure 3 System Integration Function

Roles of Each Company

Future Developments

The results of this demonstration highlight the advantages of improved operability for agricultural robots under fluctuating network conditions. We will continue working toward the practical application of these findings to help realize a new form of agriculture in Japan that integrates human expertise with robotic capabilities.

Furthermore, the high-speed closed-loop control technology for network and computing is not limited to agriculture—it offers solutions to labor and technical skill shortages faced across various industries. We will continue to promote the practical deployment and broader adoption of this technology to enable new, location-independent ways of working and to enhance labor productivity, ultimately contributing to the resolution of societal challenges in the industrial sector.

[Glossary]

1Tsukuba Forum 2025

https://www.rd.ntt/e/as/tforum/

2High-speed closed-loop control technology for network and computing

https://group.ntt/en/newsrelease/2023/05/16/230516a.html

About NTT

NTT contributes to a sustainable society through the power of innovation. We are a leading global technology company providing services to consumers and businesses as a mobile operator, infrastructure, networks, applications, and consulting provider. Our offerings include digital business consulting, managed application services, workplace and cloud solutions, data center and edge computing, all supported by our deep global industry expertise. We are over $90B in revenue and 340,000 employees, with $3B in annual R&D investments. Our operations span across 80+ countries and regions, allowing us to serve clients in over 190 of them. We serve over 75% of Fortune Global 100 companies, thousands of other enterprise and government clients and millions of consumers.

Media contacts

NTT Information Network Laboratory Group

Public Relations

Inquiry Form

NTT EAST Corporation

Corporate Strategy Planning Department, Public Relations Office

TEL: 03-5359-3711

E-mail: houdou-gm@east.ntt.co.jp

NTT AgriTechnology Corporation

Sales Solution Department

E-mail: contact@ntt-agritechnology.com

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT