Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

Climate experts are in broad agreement: a future that moves away from hydrocarbons and towards renewable energy is vital to achieve carbon neutrality in the future. Offshore wind power generation is expected to become a major source of electricity in such a future, especially for island nations like Japan.

Aiming for carbon neutrality, the Japanese Ministry of Economy, Trade and Industry's initial target is to be able to generate approximately 10 million kW of electricity via offshore wind by 2030 and between 30-45 million kW by 2040. To make this possible, around 3,600 offshore wind turbines are planned to be built along the coast of Japan by 2040.

Maintenance and operational efficiency will be vital to their continued use as the turbines are used and begin to experience wear and tear. However, the nature of wind turbines has meant that until now, inspections have required them to be switched off for the duration of the check, which naturally results in a decrease in power generation efficiency.

NTT has recently tested a way to inspect the turbines without requiring them to be switched off, which brings potential benefits for increased power generation efficiency. Inspections, in other words, that can be carried out while the turbines are still moving. The new technology could not only protect the human engineers who until now have risked their lives to inspect wind turbines while they are still moving, but cut costs: the Global Wind Turbine Operations and Maintenance Market estimated that in 2020, the market for operations and maintenance of wind turbines around the world would reach US$ 15.4 billion, hitting a figure of US$ 39.8 billion by 2031. NTT's breakthrough holds the prospect of greatly reducing this amount.

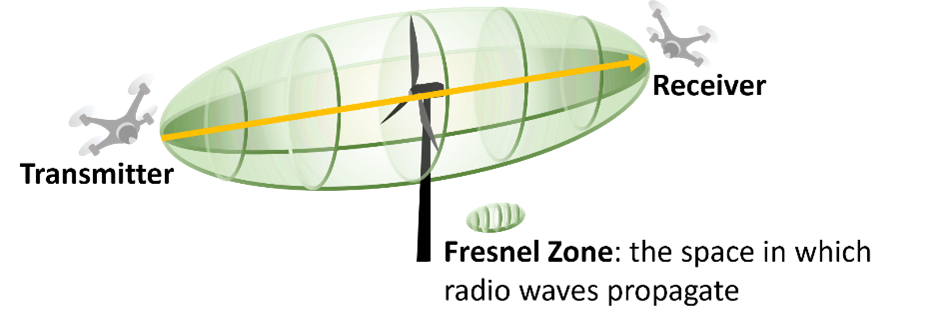

The company has pioneered wireless technology to use sets of autonomous drones that fly on opposite sides of turbines, transmitting and receiving weak radio signals as they examine the structure. The drones can detect the presence or absence of damage to turbines between transmission and reception based on changes in received signals. They do this by monitoring changes in received signals in the "Fresnel" zone--the area around a radio wave's path where obstacles can interfere with the signal.

Two drones flying around a turbine and communicating with each other can potentially detect damage, depending on slight changes in the signals sent and received within the Fresnel zone. Since the technology uses software-defined radio, transmission and reception frequencies can be easily changed as required. Moreover, since drones send and receive weak radio transmissions, there is no need to obtain a radio station license.

Before testing on real-life wind turbines, NTT recently conducted an indoor experiment to detect changes in received signals within the Fresnel zone in a laboratory. The experiment was designed to determine the state of blade damage during rotation by comparing the state of the turbine blades in action with how they would be at rest. The experiment detected the presence or absence of damage in situations where real-life repairs would require safety shutdowns. A drone in flight is usually strongly affected by noise, but NTT's countermeasures meant that weak wireless transmission and reception were enabled at an altitude of 30 meters. The company's next step is to conduct experiments using actual outdoor equipment.

Once used in real-life situations, NTT's research can contribute to carbon neutrality by increasing operational efficiency. Automating regular inspections of offshore wind turbines without switching them off will lead to increased power generation by improving facility utilization rates.

NTT--Innovating the Future of Sustainability

Daniel O'Connor.

Daniel O'Connor joined the NTT Group in 1999 when he began work as the Public Relations Manager of NTT Europe. While in London, he liaised with the local press, created the company's intranet site, wrote technical copy for industry magazines and managed exhibition stands from initial design to finished displays.

Later seconded to the headquarters of NTT Communications in Tokyo, he contributed to the company's first-ever winning of global telecoms awards and the digitalisation of internal company information exchange.

Since 2015 Daniel has created content for the Group's Global Leadership Institute, the One NTT Network and is currently working with NTT R&D teams to grow public understanding of the cutting-edge research undertaken by the NTT Group.