Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

November 3, 2022

NTT Corporation

Using light to measure particles and viscosity in liquids with ultrahigh sensitivity

- Toward application as sensors in the chemical, biology, and rheology fields that can measure at desired locations in liquids -

NTT Corporation (President and CEO: Akira Shimada) has developed an ultra-sensitive detection technology utilizing an optical fiber that can measure particles and viscosity at desired locations in liquids.

The development of technologies to detect and evaluate the viscosity of liquids and the substances in liquids with high sensitivity is vital for a wide range of use cases spanning the rheology (*1) and biology fields to medical and materials applications. Sensing technology using mechanical resonators (*2) is attracting particular attention as a simple way to perform measurements and evaluations by inserting a sensor directly into a liquid. Until now, electrical measurements using quartz resonator sensors (*3) with a diameter of about one centimeter have typically been used, but the development of new sensing technologies that can dramatically improve detection sensitivity and spatial resolution is underway.

In this research, hair-size mechanical resonators made of fine glass wire were utilized to achieve a sensing technology with high spatial resolution that can measure the fluidic properties and the mass of particles in liquids with ultrahigh sensitivity. This new sensing technology, which can be read by an optical fiber, is designed for application to IoT sensors that can perform operations difficult to achieve with conventional methods, such as high-resolution particle detection at desired locations in liquids and the characterization of local fluidic properties in non-uniform solutions.

The results were published online in the American scientific journal "Science Advances" on 2 November 2022 (EDT). This work was partly supported by JSPS KAKENHI (21H01023).

1. Background and outcome overview

The development of sensors that enable highly sensitive measurements in liquids is vital in a wide range of fields such as bio- and nano-technology. For example, mass sensors that can detect biomolecules with high sensitivity are important for medical applications such as biochips (*4). In addition, the development of sensors that can accurately evaluate the density and viscosity of spatially non-uniform liquids is important for the creation of functional fluids (*5) and applications in rheology.

Quartz resonator sensors have been commercialized as sensors that can be inserted directly into liquids to measure the fluidic properties and the mass of particles in liquids. When a quartz resonator is immersed in a liquid, its vibration characteristics are affected by the density and viscosity of the liquid. When the particles adhere, the vibration characteristics also change. Therefore, the information in the liquid can be read by measuring the vibration characteristics. Until now, electrical measurements using quartz with a diameter of about one centimeter have been widely performed, but dramatic improvements in spatial resolution and detection sensitivity have been ushering in new developments.

In this research, a mechanical resonator made of fine glass wire with a cross-section several orders of magnitude smaller than conventional sensors was utilized to achieve sensing with a high spatial resolution that can measure the characteristics of liquids and the mass of particles in liquids with ultrahigh sensitivity.

2. Experiment overview

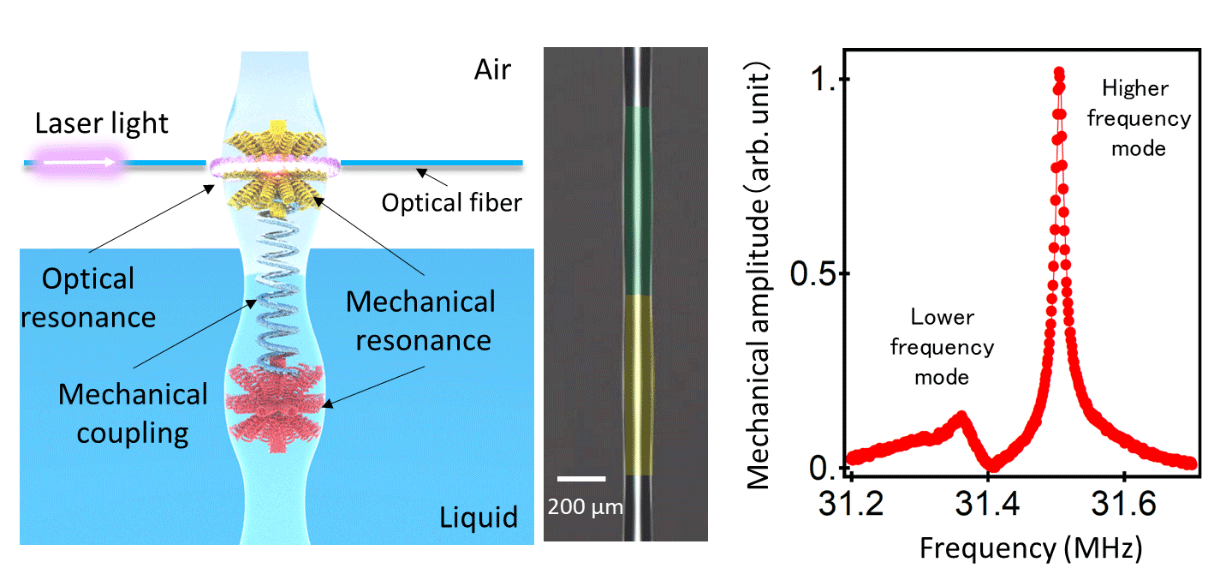

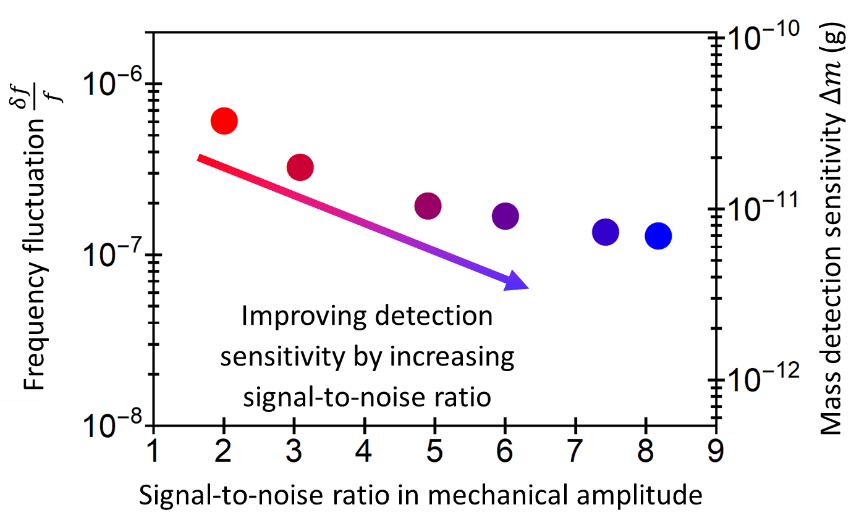

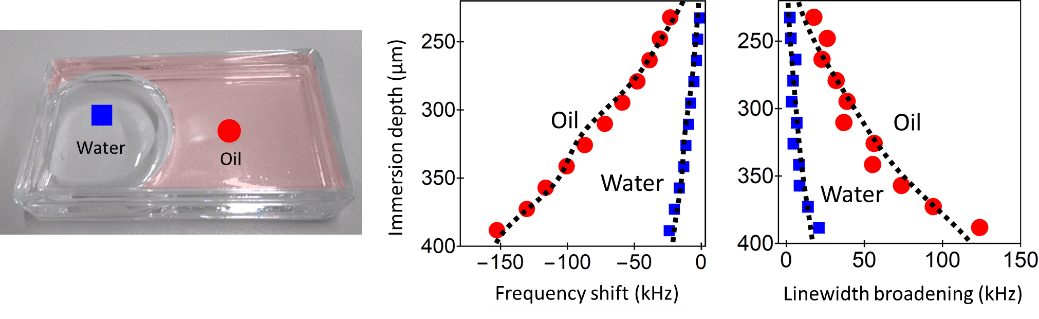

The fabricated sensing device consists of a fine glass element in the form of two connected bottles (*6). By attaching one of the bottles to an optical fiber and inserting the other into the liquid, we succeeded in detecting the mechanical vibration of the in-liquid bottle with high sensitivity using light (Fig. 1). In addition, by evaluating the amount of vibration frequency fluctuation, we found that the limit of mass detection was a few picograms (10 -12 g) (Fig. 2). This value is about three orders of magnitude better than that of conventional quartz resonator sensors and corresponds to a sensitivity that can detect a single bacterium. We also confirmed through experiments in which water and oil were phase-separated that the properties of the liquid at the desired location could be evaluated (Fig. 3).

3. Key points of technology

(1) To achieve highly sensitive measurements using light, it is essential to avoid degradation of optical properties due to light leakage into liquids. We therefore adjusted the size of the connection between the two bottles of the sensing device so that light is trapped in one (the in-air bottle) and does not leak into the liquid. Since the mechanical vibrations of the two bottles interact with each other, we can detect the vibrations of the bottle in the liquid by reading the mechanical vibrations of the bottle in air with light. This enables highly sensitive measurements that avoid degradation of optical properties.

(2) Another point that makes sensitive measurements possible is the strong light confinement in the bottle. The Q-factor, which is given as the ratio of the resonator's center frequency to the full-width at half-maximum, is the index of the degree of optical confinements. The optical Q-factor of our new sensor is 1.65 x 107, which is higher than that of conventional optical resonators. The Q-factor for mechanical resonance also influences the detection sensitivity, that is, the higher the Q-value, the easier it is to catch small vibrations. The mechanical Q-factor of our device is 2.8 × 103 in air, which is higher than that of typical mechanical resonators.

4. Future developments

This new sensing technology should enable applications that are difficult to achieve with conventional sensors, such as high-resolution detection of particles at desired locations in liquids, concentration distribution mapping of heterogeneous solutions, and local viscosity evaluation in complex liquids such as gels. The ability to coat the glass surface with metal and a self-assembled film would also enable us to utilize it as a biosensor to detect specific viruses and biomolecules in liquids. The ability to detect the signal with an optical fiber in the communication wavelength band would also expand its usage to function as an IoT sensor.

Dissertation information

"Free-access optomechanical liquid probes using a twin-microbottle resonator",

Motoki Asano, Hiroshi Yamaguchi, and Hajime Okamoto, Science Advances 8, eabq2502 (2022).

Glossary

*1Rheology

This is a general term for the area of science that deals with the deformation and flow of materials, and specifically, how materials are deformed or moved when forces act on them. It is often applied for materials that have both solid and fluid properties, such as rubber, honey, blood, and various biological tissues.

*2Mechanical resonator

This is a structure that produces mechanical periodic vibration due to elastic deformation. Guitar strings and drum membranes are two examples of a mechanical resonator. The frequency of periodic vibration (resonance) depends on the material and structure, but it is also affected by the measurement environment.

*3Electrical measurements using quartz resonator sensors

By sandwiching a quartz crystal thin film between electrodes, horizontal shear vibration of the quartz film can be electrically excited and detected. When this mechanical resonator is inserted into a liquid, the frequency of the shear vibration changes depending on the attachment of particles and/or the fluidic properties. Measurements in liquid can be performed by electrically detecting the change in the mechanical resonance.

*4Biochips

Biomolecules such as proteins and DNA are fixed on a chip to detect molecules that interact selectively with biomolecules on the chip.

*5Functional fluids

This is a general term for fluids whose specific properties or functions are created by external stimuli, electric fields, magnetic fields, light, etc. Typical examples include magnetic fluids and liquid crystals.

*6Fine glass element in the form of two connected bottles

Bottle-shaped structures can be fabricated by micromachining thin glass wires. In such a structure, mechanical resonance as the bottle expands and contracts in the radial direction appears. There is also the appearance of optical resonance, where light travels around the wall of the bottle. The mechanical and optical resonances of the bottle interact with each other due to spatial overlap, making it possible to detect and excite vibrations by light. By providing two such connected bottle structures, it is possible to detect the coupled mechanical vibrations of the two bottles using the optical resonance of one bottle.

Fig. 1: Schematic view of the fabricated sensing device (left), optical microscope image of the device (center), and its mechanical vibration characteristics in liquid (right). The yellow and green shaded area correspond to the two microbottle structures. The fine glass element in the form of two connected bottles was fabricated by micromachining a thin glass wire. Each bottle is 720 microns long, with a maximum diameter of 125 microns and a connection diameter of 115 microns. The mechanical resonances (expansion and contraction motions) of the two bottles interact with each other. By attaching optical fibers to the upper bottle, optical resonance around the upper bottle can be excited. This optical resonance and the mechanical resonance of the upper bottle spatially overlap, making it possible to read the mechanical vibration with light. Since the mechanical vibrations of the upper and lower bottles are coupled, the mechanical vibrations of the lower bottle can also be read by the optical fiber through the optical resonance of the upper bottle. By immersing the lower bottle in liquid, information in the liquid can be detected with high sensitivity without exposing the liquid to light. In the measurements, we observed both a low-frequency mode dominated by vibrations in the lower bottle and a high-frequency mode dominated by vibrations in the upper bottle.

Fig. 1: Schematic view of the fabricated sensing device (left), optical microscope image of the device (center), and its mechanical vibration characteristics in liquid (right). The yellow and green shaded area correspond to the two microbottle structures. The fine glass element in the form of two connected bottles was fabricated by micromachining a thin glass wire. Each bottle is 720 microns long, with a maximum diameter of 125 microns and a connection diameter of 115 microns. The mechanical resonances (expansion and contraction motions) of the two bottles interact with each other. By attaching optical fibers to the upper bottle, optical resonance around the upper bottle can be excited. This optical resonance and the mechanical resonance of the upper bottle spatially overlap, making it possible to read the mechanical vibration with light. Since the mechanical vibrations of the upper and lower bottles are coupled, the mechanical vibrations of the lower bottle can also be read by the optical fiber through the optical resonance of the upper bottle. By immersing the lower bottle in liquid, information in the liquid can be detected with high sensitivity without exposing the liquid to light. In the measurements, we observed both a low-frequency mode dominated by vibrations in the lower bottle and a high-frequency mode dominated by vibrations in the upper bottle.

Fig. 2: Relationship between the amount of vibration frequency fluctuation and mass detection sensitivity to signal-to-noise ratio in mechanical amplitude. When detecting particles (masses), the frequency fluctuation of mechanical vibration is key, that is, the smaller the frequency fluctuation, the higher the detection sensitivity. The frequency fluctuation can be reduced by increasing the mechanical amplitude and enhancing the signal-to-noise ratio. In this study, we introduced two types of light with different wavelengths into the fiber, one for detecting the vibration and the other for exciting the vibration using the optomechanical interaction. The signal-to-noise ratio can be enhanced by increasing the laser power for vibration excitation. We found that under the stronger excitation of the vibration with the higher signal-to-noise ratio, the frequency fluctuation is reduced and can be detected up to a smaller mass of 7.6 × 10 -12 g.

Fig. 2: Relationship between the amount of vibration frequency fluctuation and mass detection sensitivity to signal-to-noise ratio in mechanical amplitude. When detecting particles (masses), the frequency fluctuation of mechanical vibration is key, that is, the smaller the frequency fluctuation, the higher the detection sensitivity. The frequency fluctuation can be reduced by increasing the mechanical amplitude and enhancing the signal-to-noise ratio. In this study, we introduced two types of light with different wavelengths into the fiber, one for detecting the vibration and the other for exciting the vibration using the optomechanical interaction. The signal-to-noise ratio can be enhanced by increasing the laser power for vibration excitation. We found that under the stronger excitation of the vibration with the higher signal-to-noise ratio, the frequency fluctuation is reduced and can be detected up to a smaller mass of 7.6 × 10 -12 g.

Fig. 3: Photograph of the liquid phase-separated into water and oil (left) and the measured frequency shifts (center) and linewidth changes (right) of the low-frequency mode in the water and oil domains. Plots are experimental values and dotted curves are theoretical fit. Changes that reflect the difference in density and viscosity between water and oil can be observed.

Fig. 3: Photograph of the liquid phase-separated into water and oil (left) and the measured frequency shifts (center) and linewidth changes (right) of the low-frequency mode in the water and oil domains. Plots are experimental values and dotted curves are theoretical fit. Changes that reflect the difference in density and viscosity between water and oil can be observed.

For further information, please contact

NTT Corporation

Public Relation Officer, Science and Core Technology Laboratory Group

nttrd-pr@ml.ntt.com

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT