Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

May 14, 2024

NTT Corporation

Establishing a technology for high-precision measurement of pipeline shape and buried location

Toward realization of digital twin of social infrastructure

News Highlights:

- Established a technology to measure the shape and position of underground pipelines with high accuracy

- The technique directly measures the inside of the conduit, which makes it possible to measure without being affected by the installation environment (depth, surrounding buried objects, etc.)

- This technology enables us to grasp the status of facilities underground in three dimensions, and is expected to improve the efficiency of design, construction, and maintenance work in urban development, and in speeding up disaster recovery

Tokyo — May 14, 2024 — NTT Corporation (NTT) has established a technology to visualize the shape of underground conduits and measure the buried positions with an accuracy of less than 0.10% (relative measured length). This technology makes it possible to grasp the status of facilities under roads in three dimensions without requiring specialized skills, and is expected to improve the efficiency of design, construction, and maintenance work in urban development, as well as to speed up disaster recovery efforts. By applying this technology to social infrastructures such as electricity, gas, and water, we will contribute to the promotion of digital twin of all underground facilities, aiming to create a society where social infrastructures can be used safely and securely for years to come.

This technology will be introduced at the Tsukuba Forum 20241 scheduled for May 16-17, 2024.

1. Background

The social infrastructure that supports people's lives and industries faces a variety of challenges, including aging equipment, a shrinking workforce, and countermeasures against severe disasters. In response to these issues, the public and private sectors are working together to implement digital transformation (DX). NTT is also working to improve the efficiency of operations and the sophistication of maintenance and management by using the Digital Twin2 based on the 4D digital platform™3. For the social implementation of digital twin, it is important to maintain the shape and location of facilities as high-precision 3D digital information on geospatial data, which will serve as the foundation for the digital twin. Currently, data collection using satellite positioning and MMS4 is actively conducted. However, since satellite positioning cannot be used for equipment buried underground, and since actual measurement and visual inspection are difficult in many cases, obtaining equipment information accurately and efficiently has become a challenge. Among them, a huge number of pipelines installed underground nationwide5, requires highly accurate facility management from the viewpoint of urban development. However, it is difficult to quantitatively measure the shape of the pipelines that have changed due to external forces or deterioration after they are buried. Buried locations can be obtained by drawing information and radar detection from road surfaces, but it is difficult to grasp the location of equipment installed at high depths that cannot be reached by radar or places where buried objects are crowded. Therefore, technology that can measure the location regardless of the installation environment is required.

2. Technical details

Through this research, we have established a technology to visualize the shape of a pipeline using point cloud data acquired in the pipeline and measure the buried position with high accuracy. Since this technique directly measures the inside of a pipeline, it is possible to measure without being affected by depth or the surrounding environment. This technology has been verified and evaluated using communication pipelines.

< Technology Points >

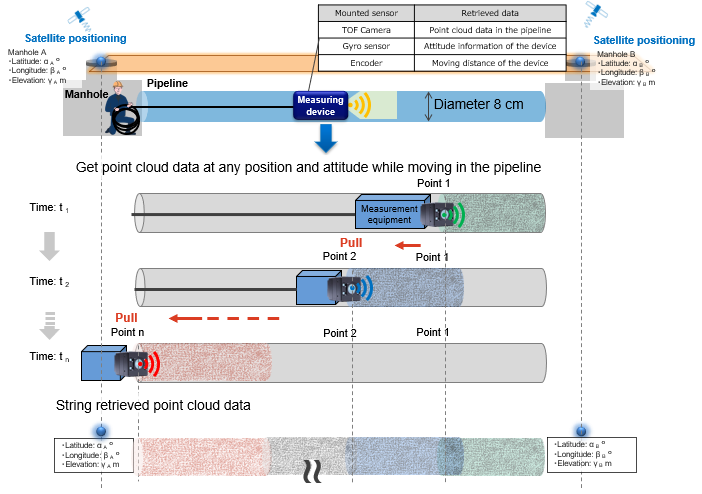

(1) Visualization of pipeline geometry

A device with a TOF camera6, gyro sensor7 and an encoder8 is used to acquire point cloud data in the pipeline. Since the inside of the pipeline is a narrow space (about Φ 8 cm) and the point cloud data that can be acquired by the TOF camera is only a few meters in front of the camera per measurement, the measuring device was pulled from the start point to the end point of the pipeline, and the point cloud data acquired continuously during the pull were connected in the longitudinal direction to visualize the shape of the entire length of the pipeline in three dimensions.

(2) Calculation of buried locations

The pipeline is equipment that connects manholes9. Since the iron cover of the manhole is exposed to the ground surface, the installation position can be accurately measured by satellite positioning. The starting point and ending point of the pipeline visualized in (1) above are combined with the location of the manhole to calculate the location of the buried conduit in geospatial space.

Figure 1 Pipeline Shape and Position Measurement Method

Figure 1 Pipeline Shape and Position Measurement Method

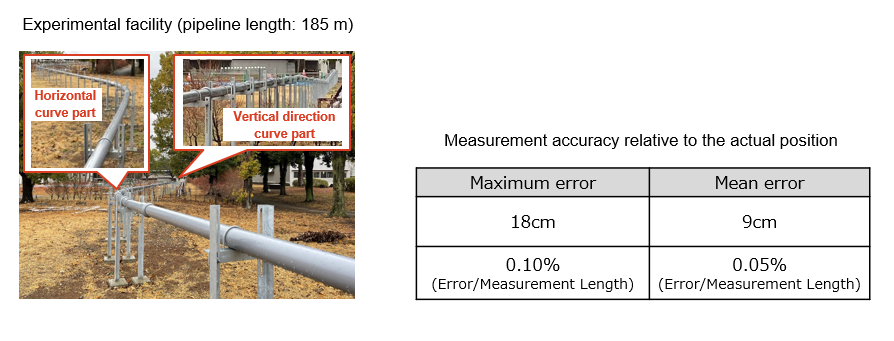

To evaluate the accuracy of this technology, we constructed a 185 m simulation facility that reproduces straight lines and horizontal and vertical bends in the same way as actual pipeline facilities, and conducted measurement experiments.

The error between the pipeline position calculated by this technology and the actual position is up to 0.10% and the mean error of 0.05%, for a measurement length of 185 m, confirming that the measurement can be performed with high accuracy.

Figure 2 Results of the Position Measurement Experiment

Figure 2 Results of the Position Measurement Experiment

3. Effects of this technology and future development

This technology makes it possible to high-precision 3D digital data on the shape and location of pipelines, regardless of the installation environment. Utilizing these data, we can reduce surveys on buried objects, reduce the risk of equipment damage during excavation, and accelerate disaster recovery, thereby contributing to more efficient and safer maintenance and management operations.

In addition, this technology can be applied not only to communication pipelines but also to similar facilities. We will contribute to the promotion of digital twin for all underground facilities by expanding the technology for pipelines such as electric power, gas, and water, and aim for a society in which social infrastructure can be used safely and securely for years to come.

1Tsukuba Forum 2024

https://www.tsukuba-forum.jp/e/index.html

2Digital twin

The digital construction of real-world twins through the digital representation of objects and people

34D digital platform™

The infrastructure that enables data fusion with various industrial infrastructures and future forecasting by collecting various sensing data on people, things, and events in real-time and matching and integrating the four-dimensional information of latitude, longitude, altitude, and time with high accuracy.

4MMS (Mobile Mapping System)

A system for acquiring spatial information such as three-dimensional coordinate data and color images of roads, buildings, and equipment while driving by mounting equipment such as laser measuring instruments, GNSS (Global Navigation Satellite System) equipment, and digital cameras on a vehicle.

5Pipeline

Pipes for storing or delivering communication/electrical cables, gas, water, etc.

6TOF (time of flight) camera

A sensor that measures distance by measuring the time it takes for infrared light to hit an object and for the reflected light to return

7Gyro sensor

A sensor that detects a change in the rotation or orientation of an object as an angular velocity and outputs an electrical signal

8Encoder

A device that measures the amount or direction of mechanical movement with a sensor and outputs it as an electrical signal

9Manhole

Structures used to install, inspect, repair, and otherwise maintain cables in pipeline equipment

About NTT

NTT contributes to a sustainable society through the power of innovation. We are a leading global technology company providing services to consumers and businesses as a mobile operator, infrastructure, networks, applications, and consulting provider. Our offerings include digital business consulting, managed application services, workplace and cloud solutions, data center and edge computing, all supported by our deep global industry expertise. We are over $97B in revenue and 330,000 employees, with $3.6B in annual R&D investments. Our operations span across 80+ countries and regions, allowing us to serve clients in over 190 of them. We serve over 75% of Fortune Global 100 companies, thousands of other enterprise and government clients and millions of consumers.

Media contact

NTT Information Network Laboratory Group

Public Relations

nttrd-pr@ml.ntt.com

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT