Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

May 16, 2024

NTT Corporation

Demonstration of remote robot control via server enhanced by softwarization of industrial Ethernet functions

Free choice of robots at factories and lower initial factory investment

News Highlights:

- Conventionally, since vendors have constructed factory systems in bulk, the selection and scalability of robots and control devices are limited.

- In a joint research with Chitose Institute of Science and Technology, we worked on the softwarization of industrial Ethernet functions and conducted a demonstration experiment to control an industrial robot with a server on April 19th, 2024. We found that the robot can be remotely controlled without any trouble and can operate with different protocols.

- This technology will enable factory systems to be rapidly constructed, and the automation of factory production lines is expected to spread to solve labor shortages in industry.

Tokyo - May 16, 2024 - NTT Corporation (NTT), in collaboration with Chitose Institute of Science and Technology, has been working on the softwarization of industrial Ethernet functions. We conducted a demonstration experiment to control an industrial robot on a server via a network. We found that the robot can be remotely controlled without any trouble and that the industrial network function can be replaced. This enables server resources in the cloud to be leveraged without needing dedicated equipment in a factory. In the future, it will be possible to construct a simple factory system, and automation of factory production lines is expected to spread to solve labor shortages in industry.

This technology will be exhibited at the Tsukuba Forum 20241 scheduled to be held on May 16th and 17th, 2024.

1. Background

In recent years, the number of workers in Japan has been decreasing, so many industries are developing manpower-saving and automation technologies to solve the labor shortage problem. Production lines at factories are also being automated.

To construct a factory that controls multiple robots, it is necessary to determine the industrial Ethernet protocol for the system and use robots and control devices that can use the protocol. However, this leads to limited selection and scalability of the robots and control devices. Moreover, since different control devices are required for each robot, we have to install many control devices in the factory. On the other hand, operation support for robots provided by emerging vendors are limited and it makes it difficult to construct systems easily.

To address these issues, NTT and Chitose Institute of Science and Technology entered into a joint research agreement in 2022 and have been working on technologies of softwarization of industrial Ethernet functions.

2. Key points of the technology

Softwarization of industrial Ethernet functions

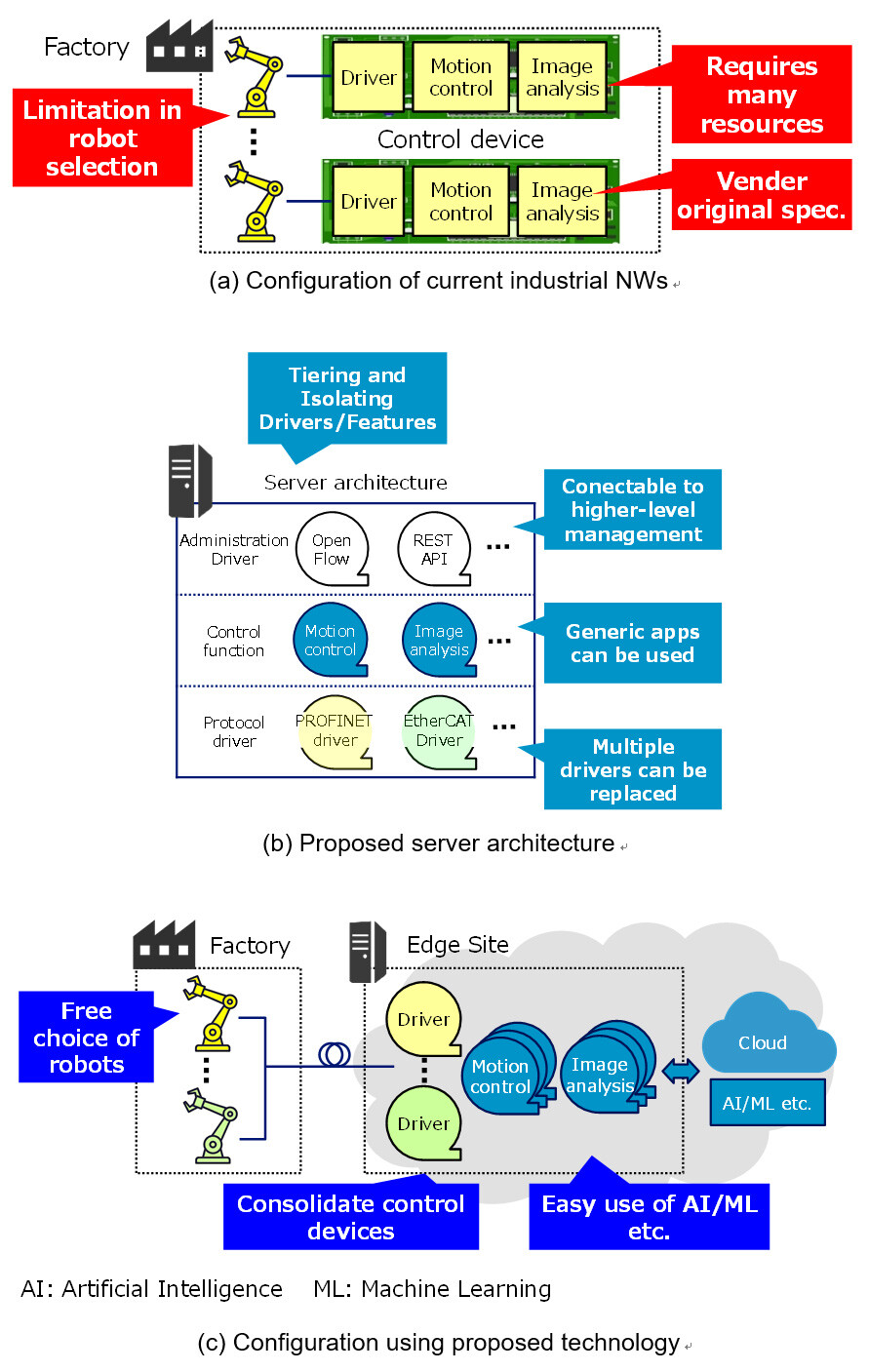

Traditionally, the protocol driver for controlling the robot and the industrial Ethernet functions for performing advanced control such as image analysis were implemented in each robot's control device and made on the basis of the vendor's own specifications (Figure 1 (a)).

NTT, in collaboration with Chitose Institute of Science and Technology, classified the industrial Ethernet functions implemented in the control device and softwarized them into a protocol driver layer that communicates with the robot, a control function layer that controls the operation of the robot, and an administration driver layer that coordinates with higher-level management devices (Figure 1 (b)). The protocol driver must be compatible with the protocol that the robot supports. The softwarization of the protocol driver and the support of multiple protocols make it possible to control the robot without depending on the robot's protocol. In addition, the control function not only controls the operation of the robot but also determines the operation by image analysis, and the softwarization enables the control function to be flexibly switched and updated in accordance with the operation contents. The administration driver is an interface that enables the cooperative control with other systems. OpenFlow2 and REST API3 support enables network and other system cooperative control.

The softwarization of the industrial Ethernet functions with a proposed server architecture enables these functions to be implemented at the edge sites, shown in Figure 1 (c). With the proposed softwarization technology, (1) robots that can use the protocol are not limited, making it possible to select a robot that meets the purpose and cost. (2) By implementing the industrial Ethernet functions for robot control on the server, the scattered control device can be consolidated on the general-purpose server. In addition, (3) general-purpose applications can be utilized for the control function, and development costs for implementing operation algorithms are expected to be reduced. Furthermore, this softwarization technology can be implemented on servers located at the edge of the network by using optical networks (IOWN APN4) such as those provided by the IOWN service.

Figure 1 Differences Between Current and Proposed Configurations

Figure 1 Differences Between Current and Proposed Configurations

3. Demonstration experiment

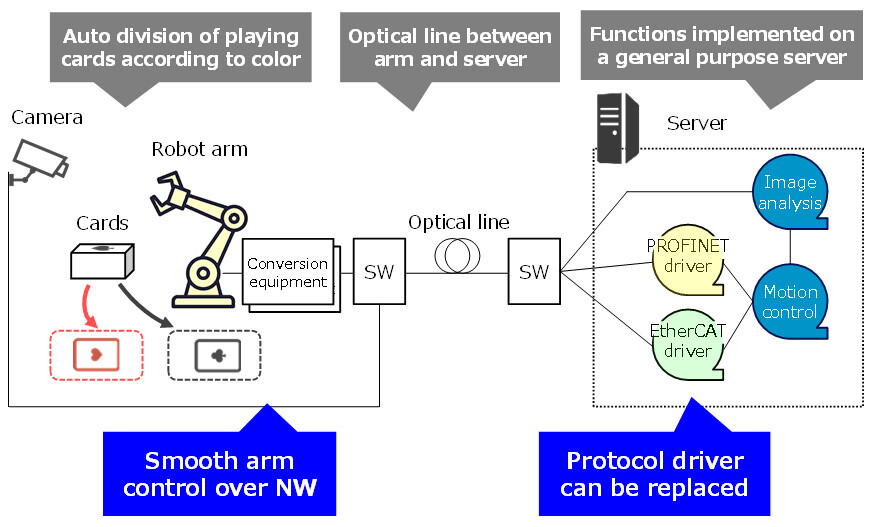

To show the effectiveness of the proposed technology, we used a general-purpose server connected to a robot via an optical line to control the robot automatically. Specifically, cameras and playing cards were placed near the robot, which was intended to be located at a factory, and image analysis, motion control, and protocol drivers were implemented on the server over the optical line, which was intended to be located at an edge site (Figures 2, 3). An experiment was conducted in which the playing cards recognized by the camera were analyzed by the server and automatically sorted in accordance with their color, and it was found that the operation could be carried out without any trouble. In addition, the protocol driver, which is one of the industrial Ethernet functions, was changed from the PROFINET5 driver implemented by NTT to the EtherCAT6 driver implemented by Chitose Institute of Science and Technology software.

Figure 2 Configuration of Demonstration Experiment

Figure 2 Configuration of Demonstration Experiment

Figure 3 Photo of Demonstration Experiment

Figure 3 Photo of Demonstration Experiment

4. Roles of each party

- NTT:

Research and development of softwarization of industrial Ethernet functions

Implementation of PROFINET driver

Use case study for demonstration experiment

- Chitose Institute of Science and Technology:

Technical advice on industrial Ethernet functions

Implementation of EtherCAT driver

Implementation of control functions and other demonstration experiment system

The demonstration experiment system was implemented and evaluated jointly.

5. Outlook

The results obtained in the demonstration experiment show that softwarization of industrial Ethernet functions can be expected to eliminate the need to install specialized equipment in the factory, enable server resources to be utilized in the cloud, which will lead to increasing the free choice of robot, and enable factory systems to be quickly constructed with less initial investment.

In the future, we will expand the functions for practical application through simultaneous control of multiple robots and field trials in actual factories so that they can be introduced into actual factory systems of small to medium-sized enterprises (SMEs). As a result, we aim to promote the automation of factory production lines to eliminate labor shortages at industrial sites more quickly.

1Tsukuba Forum 2024

https://www.tsukuba-forum.jp/e/index.html

2OpenFlow

OpenFlow is a software defined network (SDN) protocol for remotely controlling network equipment.

3REST API

Representational State Transfer (REST) is a style of Web architecture that is a collection of design principles for representing and accessing resources on the Web. A REST API is a type of API that enables external client applications to take advantage of the functionality of a Web application.

4IOWN APN

A commercial service that realizes the IOWN concept with an all-photonics network that exclusively uses optical wavelengths in all sections of the communication network.

5PROFINET

An industrial Ethernet protocol used in factory automation. The most popular protocol in the world.

6EtherCAT

An industrial Ethernet protocol used in factory automation. A protocol that enables highly accurate synchronization control.

About NTT

NTT contributes to a sustainable society through the power of innovation. We are a leading global technology company providing services to consumers and businesses as a mobile operator, infrastructure, networks, applications, and consulting provider. Our offerings include digital business consulting, managed application services, workplace and cloud solutions, data center and edge computing, all supported by our deep global industry expertise. We are over $97B in revenue and 330,000 employees, with $3.6B in annual R&D investments. Our operations span across 80+ countries and regions, allowing us to serve clients in over 190 of them. We serve over 75% of Fortune Global 100 companies, thousands of other enterprise and government clients and millions of consumers.

Media contact

NTT Information Network Laboratory Group

Public Relations

nttrd-pr@ml.ntt.com

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT