Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

November 10, 2025

NTT, Inc.

Toshiba Corporation

Manufacturing Industry's First: NTT and Toshiba Realize High-speed control of production equipment located approximately 300 km away using IOWN APN and a cloud-based PLC

~Achieving 20 ms Control Cycle and AI Visual Inspection Performance Equivalent to on-Premise~

News Highlights:

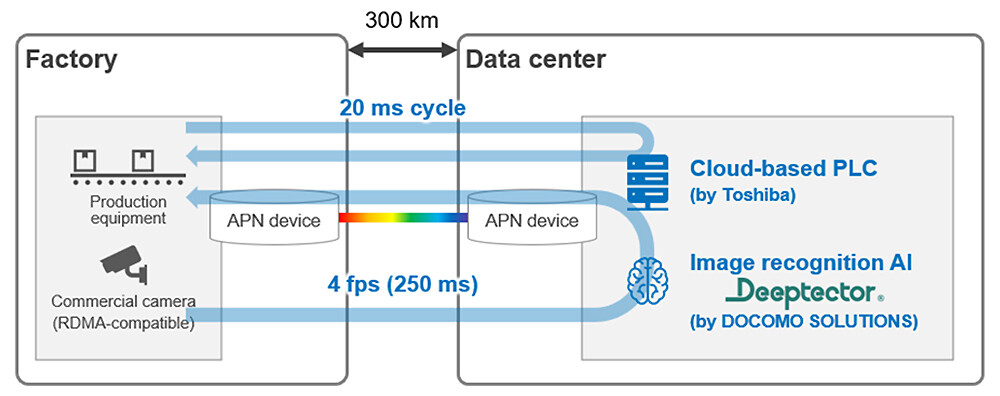

- Manufacturing industry's first*1: Realized technology verification enabling remote control within a 20 ms control cycle*2 from a site located approximately 300 km away, as well as AI visual inspection at 4 fps (250 ms)*3. Applicable to high-speed production lines such as automobile manufacturing.

- Contribution to factory DX (Digital Transformation): Cloud-based control software and AI visual inspection reduce maintenance workload and enable integrated management across multiple factories.

- Innovation using IOWN APN: A low-latency, low-jitter network leveraging photonics-electronics convergence technology meets the stringent requirements for equipment control and visual inspection in manufacturing environments, which were difficult to satisfy using conventional internet connections.

TOKYO and KAWASAKI, Japan - November 10, 2025 - NTT, Inc. (Headquarters: Chiyoda-ku, Tokyo; President and CEO: Akira Shimada; hereinafter "NTT") and Toshiba Corporation (Headquarters: Kawasaki-shi, Kanagawa; President and CEO: Taro Shimada; hereinafter "Toshiba") have jointly demonstrated the industry's first success in remotely controlling production equipment within a 20 ms control cycle from a site approximately 300 km away, and performing AI visual inspection at 4 fps (250 ms) per equipment, which meets the industry standard requirements. This was achieved through a joint experiment that leveraged All Photonics Network (APN) and RDMA acceleration technology*4, which are core technologies of NTT's IOWN initiative, together with Meister Controller Cloud PLC Package typeN1, a cloud-based PLC (Programmable Logic Controller) developed by Toshiba. As a result, even cloud-based PLC can meet a wide range of requirements equivalent to those of conventional on-premise PLCs used for controlling production lines.

This achievement enables flexible and efficient control environments through cloud migration and is expected to greatly contribute to accelerating factory DX, addressing challenges in the manufacturing industry such as labor shortages and skills transfer.

The technologies validated in this joint experiment will be introduced at NTT's exhibition booth titled "Smart Factory by IOWN" at the NTT R&D FORUM 2025*5, to be held at the NTT Musashino R&D Center from November 19 (Wed) to 26 (Wed), 2025. They will also be showcased at Toshiba's booth at IIFES2025*6, to be held at the Tokyo Big Sight from November 19 (Wed) to 21 (Fri), 2025. During IIFES2025, a remote control demonstration will be conducted by connecting the Tokyo Big Sight with the NTT Musashino R&D Center via a commercial APN.

Figure 1 Overview of the joint experiment

Figure 1 Overview of the joint experiment

Background

In the manufacturing industry, labor shortages caused by declining birthrates and aging populations, as well as the transfer of expertise from veteran engineers, have become urgent challenges. In May 2024, Toshiba became one of the first in the industry to launch Meister Controller Cloud PLC Package typeN1*7, a cloud-based PLC using internet connections, enabling cloud migration of on-premise OT systems. Until now, the company has provided cloud-based PLCs mainly for production lines with relatively moderate response requirements. However, to expand the applicable use cases, a low-latency and low-jitter network was required.

To address this need, the two companies initiated discussions and conducted this joint experiment, aiming to improve the control cycle speed of cloud-based PLCs and expand their application range by taking advantage of the low-latency and low-jitter characteristics of NTT's APN.

Research Results

In a simulated environment built at the NTT Musashino R&D Center, the companies successfully achieved remote control of production equipment within a 20 ms control cycle using a cloud-based PLC located 300 km away. By achieving a control cycle of 20 ms, it becomes possible to meet stringent requirements for high-speed control in production lines such as those in the automotive industry.

Furthermore, by combining NTT DOCOMO SOLUTIONS, Inc.'s image recognition AI solution Deeptector®*8 with NTT's RDMA acceleration technology, the companies confirmed that visual inspection of products can be performed at a level equivalent to that of an on-premise environment, even between locations separated by 300 km.

This achievement represents an important step toward advancing factory DX. Allowing PLC configuration parameters to be maintained on the cloud enables the construction of new production lines and configuration changes without requiring on-site work, reducing labor requirements and improving productivity across multiple factories. In addition, migrating visual inspection AI to the cloud enables more flexible operations and contributes to standardized quality across multiple manufacturing sites.

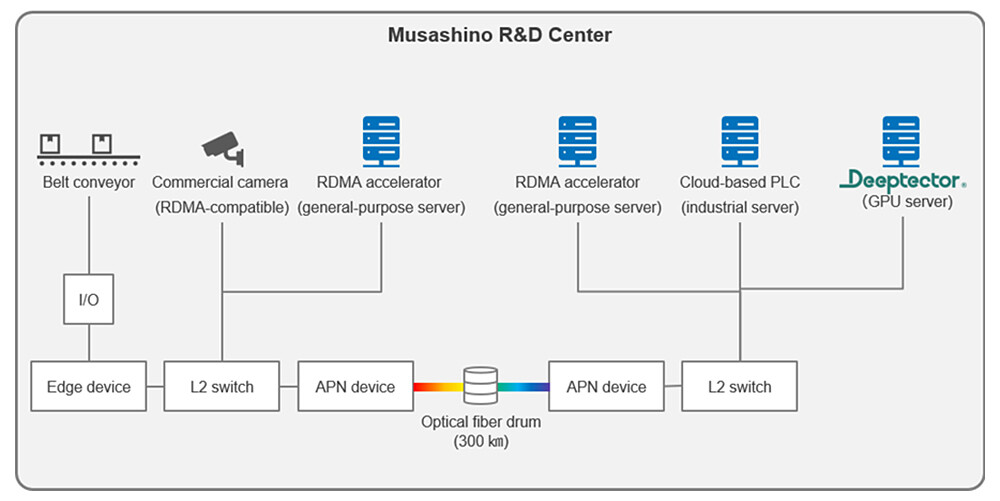

Figure 2 Experimental configuration

Figure 2 Experimental configuration

Technical Highlights

■ NTT's IOWN APN

A wavelength-network technology that provides end-to-end optical wavelength paths and aims to achieve overwhelmingly low power consumption, high-speed and high-capacity transmission, and low latency, which are difficult to realize with current electronics-based technologies.

■ NTT's RDMA acceleration technology

A technology that enables mid- to long-distance extension via APN while maintaining transfer performance for RDMA communication*9, which allows high-capacity, low-latency data transfer over short distances.

■ Toshiba's cloud-based PLC

A technology that enables cloud-based completion of control system deployment and maintenance tasks traditionally performed on-site by implementing the control core in the cloud and leveraging proprietary cloud-edge communication.

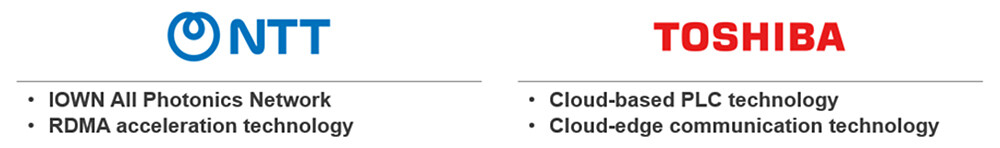

Roles of Each Company

- NTT: Construction and evaluation of the control test environment using IOWN APN and RDMA acceleration technology.

- Toshiba: Provision of industrial computers and control software, and evaluation of control cycles.

Figure 3 Roles and provided technologies

Figure 3 Roles and provided technologies

Future Outlook

NTT and Toshiba will proceed with defining detailed service specifications and organizational structures toward implementing cloud-based PLC services utilizing the APN demonstrated in this experiment, aiming for commercialization in FY2027 and beyond. In addition, based on the results of this joint experiment, the companies aim to further improve overall factory efficiency by migrating not only PLC and visual inspection AI, but also advanced computing functions such as failure prediction AI to the cloud, thereby reducing equipment management workloads, optimizing cloud resource utilization, and improving power efficiency.

[Glossary]

*1Manufacturing industry's first: Based on our internal research.

*2When using a general internet connection for control, the control cycle is typically 100 ms to 1 s.

*3This performance level sufficiently satisfies the requirements of services (such as inspection and reporting using image processing) that NTT DOCOMO SOLUTIONS, Inc. has provided to various customers since it launched its image recognition AI solution (Deeptector®) in 2017.

*4RDMA acceleration technology: A technology that extends RDMA communication without requiring changes to how applications use RDMA, by pseudo-generating loopback signals on the terminal side to confirm whether RDMA transmission has succeeded.

*5NTT R&D FORUM 2025 IOWN ∴Quantum Leap official website: https://www.rd.ntt/e/forum/2025/

*6IIFES2025: One of the largest technology exhibitions in Japan focused on DX (Digital Transformation), automation, and AI utilization in the manufacturing industry. https://iifes.jp/

IIFES2025 Toshiba Group website: https://www2.toshiba-infrastructure.jp/exhibition_smart-manufacturing/iifes2025.html

*7Meister Controller Cloud PLC Package typeN1: A PLC capable of performing control in the cloud. By placing the control core in the cloud, remote control and maintenance become possible. Real-time operational data can be accessed in the cloud, enabling new value such as digital twins and AI collaboration.

*8Deeptector®: https://www.nttcom.co.jp/deeptector/

Deeptector® is a registered trademark of NTT DOCOMO SOLUTIONS, Inc.

*9RDMA communication: A technology widely used for short-distance data transfer in data centers, high-performance computing, and real-time systems, enabling direct memory-to-memory data transfer over a network.

About NTT

NTT contributes to a sustainable society through the power of innovation. We are a leading global technology company providing services to consumers and businesses as a mobile operator, infrastructure, networks, applications, and consulting provider. Our offerings include digital business consulting, managed application services, workplace and cloud solutions, data center and edge computing, all supported by our deep global industry expertise. We are over $90B in revenue and 340,000 employees, with $3B in annual R&D investments. Our operations span across 80+ countries and regions, allowing us to serve clients in over 190 of them. We serve over 75% of Fortune Global 100 companies, thousands of other enterprise and government clients and millions of consumers.

About Toshiba

In 2025, the Toshiba Group celebrates its 150th anniversary. As the company looks ahead, it is enhancing its management structure, streamlining operations, and investing in forward-looking businesses to build foundations for new growth. This will allow it to continue to support advances toward a sustainable future with products and services developed by its wide range of businesses in the energy, infrastructure, and electronic devices domains.

Guided by its corporate philosophy, "Committed to People, Committed to the Future.," Toshiba brings industry-leading capabilities in green transformation (GX) and digital transformation (DX) to solutions for companies addressing the many challenges faced by modern society. By leveraging the power of data derived from its constantly evolving products and solutions, the Group is determined to help to achieve carbon neutrality and a circular economy.

In fiscal year 2024, Toshiba Group recorded annual sales of 3.5 trillion yen and employed 95,000 people worldwide. For more information, visit our website or follow us on LinkedIn

.

Media contacts

NTT, Inc.

NTT IOWN Integrated Innovation Center

Public Relations

Inquiry form

Toshiba Corporation

Media Relations Group

Inquiry Form

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT