Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

November 9, 2023

NTT Corporation

Improvement of working environment and safety of construction work by remote operation of construction equipment and monitoring of site environment by IOWN APN

Tokyo - Nov. 9, 2023 - NTT Corporation (NTT), in cooperation with other companies, has confirmed that the IOWN All-Photonics Network (APN) [1], which has characteristics of high capacity, low delay and fixed delay, can be used to connect construction machinery at the site with a remote-control system, thereby enabling remote control without discomfort in use cases using two types of construction machinery with different applications. In addition, by transmitting images and other information at the site with a low delay, operators in remote areas can accurately grasp the site conditions, making it possible to realize an environment close to working at the site. In the future, the use of remote control of construction equipment is expected to improve the efficiency of operations, such as reducing the travel time of operators, and improve safety by reducing dangerous work performed by people on site.

The results will be displayed at the NTT R&D Forum - IOWN ACCELERATION [2] held from November 14th to 17th, 2023.

1. Background

In the construction industry, labor shortages, long working hours, and the aging of engineers are becoming more serious. In addition, since the upper limit on overtime work will be enforced from fiscal 2024, work style reforms such as work efficiency and employment diversification are required. Expectations are high for solving problems by remote control of construction machinery.

Although remote control of construction equipment has begun to be introduced at actual construction sites, it has not yet been widely used due to the limited use cases and areas in which it can be used, such as digging soil and loading it into dump trucks on large sites.

Further improvement of operability and security of safety have been issues to promote utilization in various use cases such as expansion of full-scale use areas, and application to more precise on-site processes.

2. Details of demonstration

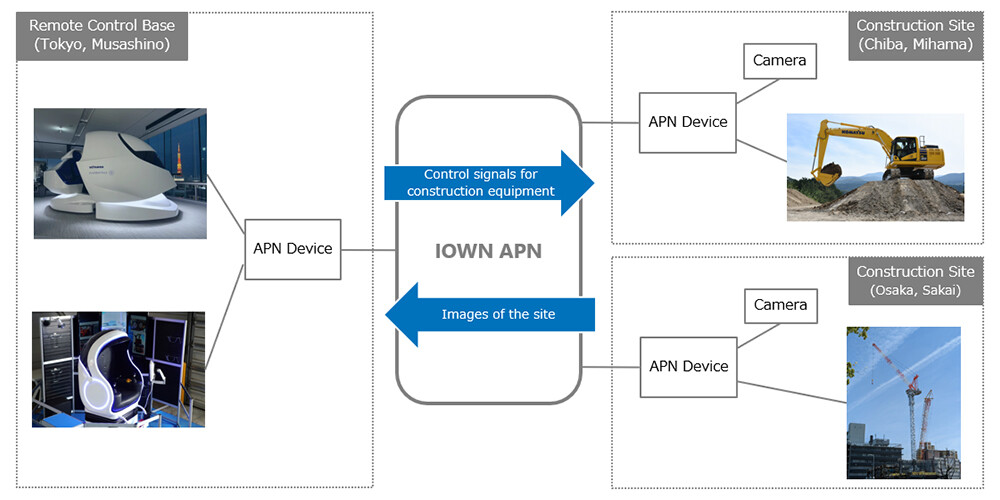

To verify the effectiveness of remote control of actual construction equipment from remote offices, we set up a remote-control cockpit at the NTT Musashino Research and Development Center, installed construction equipment at remote sites, connected the two sites via APN, and built a network to verify remote control and remote confirmation of the site environment.

In the following two use cases, in which the base and the target construction equipment are different, we have demonstrated the of remote operation of the construction equipment by transmitting the control signal of the construction equipment and the video of the site with low and fixed delay.

Figure 1 Demonstration Image

Figure 1 Demonstration Image

■ Use case for remote control of hydraulic excavator in combination with radio

A Komatsu hydraulic excavator was installed at the Komatsu IoT Center Tokyo in Mihama Ward, Chiba Prefecture. Using a remote-control system jointly developed by Komatsu and EARTHBRAIN, we demonstrated remote control via APN and real-time confirmation of the on-site environment.

In this demonstration, we confirmed that the remote-control system can be used in a variety of environments, improving operability by combining APN and radio to further reduce delay, and improving convenience by creating a faster environment in the field. In addition, NTT's ultra-low delay video-transmission technology [3] enables operators in remote areas to accurately grasp the situation in the field by transmitting images in 4K high resolution without deterioration of image quality, which is expected to improve the work environment and safety in the future.

■ Use case for remotely controlling stationary tower cranes with end-to-end wired connections

Using the tower crane remote control systems TawaRemo® and [4] installed at the West Japan Equipment Center of Takenaka Corporation (Sakai City, Osaka Prefecture), remote control via APN was demonstrated. Regarding the video transmission of TawaRemo®, we demonstrated the operation of real-time video transmission by combining APN with the real-time remote work support platform "JIZAIPAD" equipped with Jizaie's low-delay video transmission technology.

In this demonstration, it was confirmed that remote operation can be achieved within an acceptable delay value of 500msec, which is specified to ensure the quality of remote operation by skilled operators, by connecting to the tower crane via APN and realizing remote operation using the characteristics of APN, which has low and fixed delay over the approximately 500km distance between Tokyo and Osaka. By using the low latency and fixed delay characteristics of APN over the 500 km distance between Tokyo and Osaka, we have confirmed that it is possible to achieve remote operation of lifting [5] and other operations within an acceptable delay value at all times. In addition, by taking into account the fixed delay characteristics of APN,, we were able to further reduce the buffer time in the low-delay video-transmission technology provided by Jizaie, and confirmed its effectiveness for real-time video-transmission.

3. Outlook

Through this demonstration, we confirmed that remote control has the potential to improve the working environment, increase efficiency, and enhance safety.

Based on the findings of this demonstration, we will expand application areas and use cases, as well as expanding the value provided through a combination of monitoring construction sites with drones, and contribute to solving social issues such as improving long working hours and securing diverse human resources in the construction industry.

< Glossary >

[1]IOWN APN (All Photonics Network)

The IOWN is comprised of three components: the "All Photonics Network (APN)," which makes it possible not only for networks but also for terminal processing; the "Digital Twin Computing," which enables advanced and real-time interaction between objects and humans in cyberspace; and the "Cognitive Foundation," which efficiently deploys various ICT resources including these.

By introducing new optical technologies from the network to terminals and chips, APN achieves ultra-low power consumption and ultra-high-speed processing, which has been difficult to achieve. By operating on a single optical fiber with wavelengths assigned to each function, it is possible to provide multiple functions that support the social infrastructure, such as information communication functions and sensing functions represented by the Internet, without interfering with each other.

https://www.rd.ntt/e/iown/

[2]"NTT R&D FORUM 2023 -IOWN ACCELERATION" Official Website

https://www.rd.ntt/e/forum/2023/

[3]Ultra-low delay video-transmission technology

Uncompressed video transmission technology capable of transmitting and receiving up to 8K120p video in the SMPTE ST 2110 standard through an optical path. Video transmission technology that enables long-distance and low latency video transmission by direct acquisition of SDI signals into optical transmission equipment and direct transmission as uncompressed SMPTE ST 2110 streams over a high-capacity optical path.

https://group.ntt/en/newsrelease/2022/02/22/220222a.html

[4]TawaRemo®

A tower crane remote control system jointly developed by Takenaka Corporation and Kajima Corporation with Aktio Corporation.

[5]Lifting

Lifting materials and heavy goods using machines such as cranes and forklifts, and other machinery.

About NTT

NTT contributes to a sustainable society through the power of innovation. We are a leading global technology company providing services to consumers and business as a mobile operator, infrastructure, networks, applications, and consulting provider. Our offerings include digital business consulting, managed application services, workplace and cloud solutions, data center and edge computing, all supported by our deep global industry expertise. We are over $95B in revenue and 330,000 employees, with $3.6B in annual R&D investments. Our operations span across 80+ countries and regions, allowing us to serve clients in over 190 of them. We serve over 75% of Fortune Global 100 companies, thousands of other enterprise and government clients and millions of consumers.

Media contact

NTT

Public Relations, NTT IOWN Integrated Innovation Center

nttrd-pr@ml.ntt.com

Information is current as of the date of issue of the individual press release.

Please be advised that information may be outdated after that point.

NTT STORY

WEB media that thinks about the future with NTT