Microsoft ends support for Internet Explorer on June 16, 2022.

We recommend using one of the browsers listed below.

- Microsoft Edge(Latest version)

- Mozilla Firefox(Latest version)

- Google Chrome(Latest version)

- Apple Safari(Latest version)

Please contact your browser provider for download and installation instructions.

September 19, 2019

Transmits three movies' worth of images in one second! "JUPITER", the world's fastest submarine cable system, will convey the excitement and inspiration of Tokyo 2020 to the world

Mr. Takeru Sakairi & Ms. Miho Kanzaki

Interview with the people in charge of developing the JUPITER submarine cable system

In October 2017, the NTT Group established a consortium comprising six companies with SoftBank, Facebook, Amazon, PLDT (a leading Philippines telecommunications provider), and PCCW Global (a leading Hong Kong telecommunications provider) and began constructing "JUPITER", a large-capacity optical submarine cable system linking the United States, Japan, and the Philippines. Construction is currently scheduled for completion in March 2020 and the work of laying the cables in the ocean is continuing.

Measuring a total length of approx. 14,000 km, "JUPITER" is a submarine cable system linking the United States, Japan, and the Philippines and realizes wavelength division multiplexing of 400 Gbps per second, making it the fastest submarine cable system between the United States and Japan. "JUPITER" has the speed to transmit approx. six hours of high vision images (approx. three movies) in just one second.

The JUPITER submarine cable system is being constructed not only to enable commencement of 5G services and convey the excitement and inspiration of Tokyo 2020 to the world, but also meet demand for a gigantic network across Asia and the Pacific Ocean. We spoke with Mr. Takeru Sakairi, who manages the development, design, and laying work for the JUPITER submarine cable system, and Ms. Miho Kanzaki, who is responsible for obtaining the necessary approval and authorization from the American and Japanese Governments.

This is an interview as of September 2019.

In charge of developing the JUPITER submarine cable system

Mr. Takeru Sakairi

NTT Ltd. Japan Corporation

ICT Infrastructure Services Department

Responsible for technological managment of submarine cable system construction and construction works.

Joined the JUPITER project in October 2017. A recent hobby is taking photographs of his daughter.

Ms. Miho Kanzaki

NTT Ltd. Japan Corporation

ICT Infrastructure Services Department

Performs roles ranging from submarine cable system planning and design to consortium facilitator.

Responsible for obtaining the necessary approval and authorization from the Japanese Government and the American Government.

Table of Contents

- What is a submarine cable system?

- Background to the development of "JUPITER", which has the world's fastest transmission capacity

- Submarine cable system incorporating risk managment for natural and other disasters

- Presence of the NTT increasing among the six consortium member companies

- Reaching even deep sea depths of 8,000 meters! Delicate submarine cable system-laying technology

- A project that requires not only development but also coordination with fishermen, administration, and government

- "JUPITER" is a point along the way as innovation aimed at the realization of Smart World continues

What is a submarine cable system?

Submarine cable systems are said to currently provide approx. 99% of international telecommunications services. With the demand for telecommunications since the spread of the Internet in the 2000s in particular, telecommunications carriers in various countries have been developing continent-connecting high-performance submarine cable systems and laying cables throughout the world's oceans.

Background to the development of "JUPITER", which has the world's fastest transmission capacity

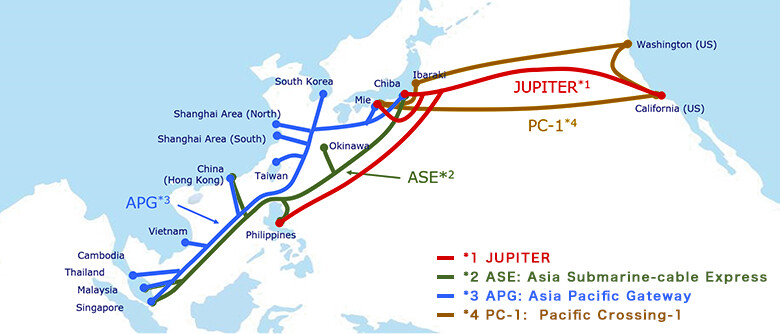

Measuring a total length of approx. 14,000 km, "JUPITER" is a submarine cable system linking the United States, Japan, and the Philippines. It is the fourth submarine cable system for the NTT Group linking the Pacific Ocean and Asian regions.

"Jupiter" is, of course, the name of the largest planet in our solar system, but for this project, "JUPITER" stands for "Japan U.S. Philippines IT Express Route".

Map showing submarine cable system of "JUPITER" and NTT Com

Map showing submarine cable system of "JUPITER" and NTT Com

Ms. Kanzaki: Demand for international data communications volume is continuing to increase more and more. Communications volume in Asia is especially increasing, and demand for cables to be laid in the Pacific Ocean is increasing. In a few years' time, we will probably be unable to keep up with demand with existing cables alone, and if preparations are not made now, there will be insufficient capacity for providing various services. This is why this project was launched.

Mr. Sakairi: In consideration of the launch of 5G services in 2020 as well as anticipated growth in data communications volume for a range of services such as "clouds" and "data center activities", it was decided that it would be best to create a new cable. It was also determined that constructing a new cable was necessary for business in the future.

The interviewees said that JUPITER incorporates devices with cutting-edge specifications that are the fastest in the world.

Mr. Sakairi: "JUPITER" incorporates the latest transmission device, called "SLTE". Capable of transmitting 400 Gbps per wave, this high-tech device applies the very latest transmission technology. In terms of high vision images, the device is so fast that it is capable of transmitting approx. Three movies' worth of images in one second. You can say that it is currently the fastest in the world!

Submarine cable system incorporating risk managment for natural and other disasters

In the 2011 Great East Japan Earthquake, submarine cable systems also suffered tremendous damage. The NTT Group's submarine cable system also had strongly constructed cables along the coast bent and twisted by the tidal wave, disrupting telecommunications. It can be said that JUPITER's design incorporates the lessons learned from this catastrophe.

Ms. Kanzaki: JUPITER has four cable landing stations: the Shima Cable Landing Station (Mie Prefecture, Japan), Maruyama Cable Landing Station (Chiba Prefecture, Japan), Daet Cable Landing Station (Philippines), and Los Angeles (California, USA). The system's cable branching devices are equipped with the very latest WSS (WSS ROADM: Wavelength Selective Switching Reconfigurable Optical Add Drop Multiplexing).

For example, say telecommunications usually use the Chiba--US route. When the cable is cut due to an earthquake or other event, all of the traffic can be switched remotely to the Mie--US route.

In the Great East Japan Earthquake, cables that should be held strong were bent by the tremendous force of the ebb tide. Cable branching devices equipped with WSS were installed on the outer side of the Japan Trench, but because ebb tides stop at the Japan Trench, the ebb tides apparently have no effect.

Presence of the NTT increasing among the six consortium member companies

Facebook and Amazon are two participating companies in the JUPITER Project. It can be said that within the six-company consortium, high expectations are held for the NTT Group companies to provide not only technology but also NTT's previous experience, expertise, and operational know-how.

Mr. Sakairi: NTT has the role of providing cable landing stations in Los Angeles in the US and Shima in Japan. In order to land cables it is necessary to obtain the permission of the national government, and so Ms. Kanzaki is working with the FCC (Federal Communications Commission), the licensing authority for the United States Federal Government. This is an extremely important role within the consortium.

Ms. Kanzaki: I made a presentation to Federal Communications Commission (FCC) in Washington D.C. The US Government also has an organization called "Team Telecom", which comprises representatives from the FBI, Department of Homeland Security, Department of Defense, and Department of Justice, and I also made a presentation to these people. I was really nervous. (Laughs.)

The interviewees said that NTT plays many other roles within the consortium as well.

Mr. Sakairi: In providing cable landing stations, NTT is not just providing station buildings and equipment. NTT has staff who work at the cable landing stations as well as the NOC (Network Operation Center), a department responsible for monitoring submarine cable systems, and WE Marine (NTT World Engineering Marine), a company that lays, operates, and maintains cables. You could say that this project brings together the total power of the NTT Group. Currently, cable laying is beginning in the ocean near Japan, and WE Marine's cable-laying ship SUBARU is laying the cables.

Reaching even deep sea depths of 8,000 meters! Delicate submarine cable system-laying technology

The interviewees described how the technology for laying cables over a distance of approx. 14,000 km is even more complex and delicate.

Mr. Sakairi: The thick cable (on the left in the photograph) is used in shallow water. It has protection to ensure that that cable is not cut even if it gets caught on the fishing tackle of fishermen fishing in shallow waters or the anchors of commercial boats. Also, in shallow water the cable is buried in the mud on the ocean floor. The cable is dropped from the laying ship and buried remotely using a machine similar to a plow used in farming, the cable released gradually and buried in the trough dug by the machine.

Ms. Kanzaki: The depth at which cables are buried in shallow waters differs from country to country. In Japan, it is around 1.5 m, but in other countries it can be 3 m, 5 m, or even 10 m. For example, Singapore is a distribution base and is visited by many tankers, and so it is prescribed that cables are buries at around 10 m below the seabed.

Mr. Sakairi: The thin cable (on the right in the photograph) is a type of cable that is laid on the seabed at depths of 4,000 m, 5,000 m, and 8,000 m at the deepest. In deep waters, there is little risk of the cable being damaged by external elements such as tankers, and so thin cables such as this are laid on the surface of the seabed rather than being buried.

Ms. Kanzaki: It's amazing that at a depth of 8,000 m, the seabed has a proper layer of mud and sand and the cable can lie on it properly.

Mr. Sakairi: Certainly. The cable has to be pulled at an appropriate tension to ensure that sections of it does not twist. Conversely, it is not good for the cable to be pulled too tight, achieving "appropriate tension" is important. Before cables are laid, sensors and sonars are used, topographical surveys are conducted, and appropriate ship speeds and cable release speeds are calculated using simulations.

However, due to weather influences such as typhoons and high waves, it is difficult to lay cables continuously for 24 hours, and so the laying schedule is apparently managed while taking uncertainties into consideration.

A project that requires not only development but also coordination with fishermen, administration, and government

Mr. Sakairi: Since the construction work is in the ocean, it is vital to ensure safety aspects so that accidents between ships do not occur. Construction work is carried out after fishermen, administrative bodies, the Ministry of Defense, the Coast Guard, and other organizations have been notified.

Mr. Sakairi said that no effort was spared in laying the cables to proactively establish communication with local fishermen by frequently visiting ports in addition to holding explanatory meetings for fishery cooperatives.

Ms. Kanzaki: I was responsible for preparing the American cable landing station facilities, and making adjustments to ensure that facilities agreeable to all six consortium member companies were constructed was extremely difficult. Searching and negotiating for optimal solutions producing advantages for each of the six member companies was tremendously difficult.

Laying this one submarine cable system was made possible by not only design, technology, development, and construction, but also the various effortsof each consortium member.

"JUPITER" is a point along the way as innovation aimed at the realization of Smart World continues

Mr. Sakairi: Of course, considering the future demand for and growth of IT, "JUPITER" alone will be insufficient. We want to catch-up with the latest technology in preparation for constructing the next cable with a view to the future. Furthermore, we wish to also extend these technologies to other consortium members and cultivate human resources for creating the next system. Moving forward, I intend to be conscious of this in my work activities.

Like the JUPITER Project consortium, it is anticipated that there will be diversification of companies participating in such projects. Thus it is anticipated that expectations for the NTT Group to provide not only the latest cable-laying technology but also landing station maintenance and operation will grow even higher.

Ms. Kanzaki: Speaking of human resources, the NTT Groups has quite a large number of highly skilled staff--the cable construction team, cable landing station staff, and cable-laying/-operating workers, etc.

Mr. Sakairi: Including people in positions such as Ms. Kanzaki, I think there are very few companies in the world that are capable of undertaking total cable construction and management to this extent.

Mr. Sakairi also said that data communications volume in Asia continued to increase explosively. In particular, Japan will no doubt strengthen its presence as a "hub" linking Asia and the world.

As a symbol of this, it is thought that the JUPITER submarine cable system connecting the US, Japan, and the Philippines will further strengthen its presence as a legacy for the next generations.

It is no exaggeration to say that the history of telecommunications in Japan, an island nation surrounded by the ocean, is the history of submarine cable systems. Based on the submarine cable system technology built up from the days of the Ministry of Communications and Transport via the former Nippon Telegraph and Telephone Public Corporation, the NTT Group will continue to evolve and take on new challenges and will undoubtedly fulfill an important position in the submarine cable system of the future--a field that can be regarded as holding even higher expectations for achieving innovations leading to a Smart World as well.